04 Aug Airbus Completes First ‘Wing of Tomorrow’ Prototype

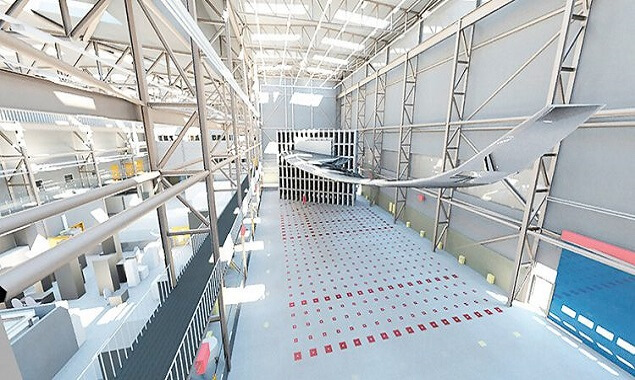

Airbus recently completed the first full-size prototype for the company’s ‘Wing of Tomorrow’ research program, which is being undertaken at its Advanced Manufacturing Research Centre here. The program involves testing the latest composite materials and new technologies in aerodynamics and wing architecture, and explores how wing manufacturing and industrialization can be improved to meet future market demands as the aerospace sector emerges from the pandemic.

Subassembly of the first prototype’s complex wing cover took place at Airbus’ Filton, England, site. The wing cover and the fixed trailing edge (made by GKN Aerospace) were then delivered here for assembly.

Three full-size prototype wings will eventually be assembled: one to understand systems integration; a second to be structurally tested to compare against computer modelling; and a third to test scaling-up production for comparison with industrial modelling. The prototypes feature more than 100 new manufacturing and assembly techniques, with the goal of making aviation more sustainable.

“High-performing wing technology is one of several solutions, alongside sustainable aviation fuels and hydrogen, we can implement to contribute to aviation’s decarbonization ambition,” notes Sabine Klauke, chief technical officer of Airbus. “Wing of Tomorrow is also an example of how large-scale industry collaboration will be critical to achieving our sector’s agenda for a more sustainable future.”

Wing of Tomorrow is being part-funded by the UK Government through the Aerospace Technology Institute. It involves global partners and teams across Airbus’ European sites, including Bremen in Germany, where the ‘Wing Moveables’ team is based.

Source: https://www.assemblymag.com/articles/96805-airbus-completes-first-wing-of-tomorrow-prototype