03 Nov Your Digital Copy in the Virtual World: Digital Twins

With the technological advancements our age, the digital world has become an integral part of our lives. This digital transformation has not been limited to just social media, entertainment, and communication tools; it has also reshaped many processes for companies, such as marketing and R&D. One of the technologies introduced in this new era is the concept of “Digital Twins.” So, what is a digital twin, and how does it work?

What is a digital twin?

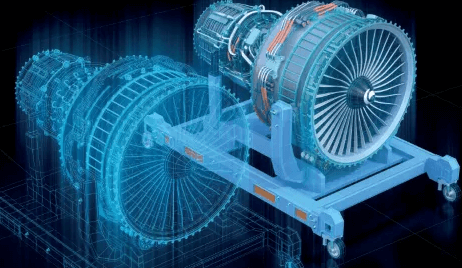

A digital twin is the name given to a virtual copy of a physical object, system, or process that exists in the real world. Digital twins mimic the behavior and appearance of the physical objects, systems, or processes they represent, allowing for prediction and optimization of various scenarios that may arise over time.

How does digital twin technology work?

Over the course of human history, scientists have developed various rules and formulas to explain the behavior of objects. Using these rules, we can predict the behavior of an object based on various information, such as its velocity and weight. Digital twins can predict the current state of an object using sensor data by applying these rules. As a result, a digital twin exhibits similar behavior to the physical version of an object. However, in cases where the physical rules are uncertain, especially when predicting human behavior, digital twins use complex models that mimic human behavior to achieve results closest to reality. To accurately represent the system that digital twins emulate, the relevant system must be converted into a three-dimensional digital form. Therefore, the system is scanned with system scanners and converted into a three-dimensional model. If there are entities in the system, such as buildings, that are too large to be scanned, architectural drawings, 3D modeling, and images taken by drones are used to create a three-dimensional model of the system.

What is the difference between digital twins and simulations?

According to IBM, the main difference between digital twins and simulations is that digital twins create a virtual environment. The most significant difference between digital twins and simulations is their scope; simulations usually focus on limited predictions within a specific process, while digital twins attempt to mimic the real world in many aspects, allowing various simulations to be run through digital twins. Another distinguishing feature is that digital twins are fed with real-time data such as sensor data. As a result, digital twins are updated in real-time and can adjust their predictions about the future based on this updated data, enabling two-way communication between digital twins and the system.

What are the applications of digital twin technology?

Some of the use scenarios for digital twins are as follows:

- Digital twins will enable more effective designs in R&D and design processes. For example, Volvo can be cited as an example. Volvo reduces the need for physical prototyping by using digital twin technology. Volvo also improves its designs by monitoring in-car behaviors with digital twins.

- Tracking the supply chain through digital twins can provide advance predictions of potential issues, such as bottlenecks. For example, FedEx has created digital twins for its distribution networks. This allows FedEx to test potential issues during the distribution process in a digital environment and make faster decisions.

- Companies can analyze their processes using digital twins, and proposed changes in these processes can be tested in a virtual environment, allowing these changes to be implemented more quickly and securely. Siemens, for example, offers digital twin products that facilitate the improvement of company processes.

- Training and testing the artificial intelligence behind autonomous vehicles can be done in a virtual environment with the help of digital twins. Examining the impact of various real-life conditions and issues that arise as a result of AI behavior will make the development of autonomous vehicles safer.

- In the field of sales and marketing, products can be displayed and sold in a virtual environment using digital twins. This allows customers to test products without physically needing to visit brick and mortar stores.

- Using digital twins, companies can simulate the demographic they target, enabling the prediction of customer behavior and the establishment of systems that learn from changing customer behavior. This allows marketing departments to provide better services to customers and take advantage of emerging opportunities more effectively. In Gartner’s Hype Cycle blog, it is predicted that the widespread use of digital twins in this field will begin within 10 years.

How can we use digital twins in the aviation industry?

Digital twins can be fed with sensor data from complex systems inside aircraft and can predict potential issues that may arise inside the aircraft. This allows for taking precautions against problems that may occur during flights.

- For example, Rolls Royce’s aircraft engine has a real-time digital twin that is constantly updated. Data from this digital twin can be used to make predictions, such as when the engine will need maintenance. Additionally, potential scenarios such as wear and tear, heating, or malfunctioning of engines can be tested safely using digital twins.

- Data that is typically challenging to track can be visualized and monitored using digital twins. For example, General Electric can display real-time temperature data for aircraft parts using digital twin products. Furthermore, power outages at company sites or electrical issues within the aircraft can be predicted using these digital twins before problems occur.

- Carbon emissions during flights can be predicted using digital twins, and this data can be used to minimize the carbon emissions of aircraft during flight planning. Additionally, aircraft designs that minimize carbon emissions can be produced using this data during the aircraft design phase.

- Digital twins can be used to provide training in pilot training. This enables training on a wider range of scenarios, providing pilots with a more realistic flight experience.

- Inventory and supply chains in areas such as catering and cargo can be tracked using digital twins. This allows for predictions of deficiencies before they occur, making decisions in the face of issues easier.